The Massey Ferguson 35X Tractor

Following the acquisition of Perkins Engines by Massey Ferguson in the late 1950’s, the Perkins power unit was then specified in the majority of MF products going forward. Use of the Perkins P3 diesel engine in the TE20 tractor provided an insight as to the benefits of an agricultural version of a long stroke three cylinder indirect Development by Perkins on this engine family had resulted in a modern high speed injection system, this having been specified as a factory option for the Yugoslavian market as well as a conversion kit for tractors already in the field.

Development by Perkins on this engine family had resulted in a modern high speed diesel fuel unit of 152.6 cubic inches capacity (2.5 litres). Its 3 cylinder unforget¬table exhaust note quite different to any other diesel engine of similar capacity. Availability of an agricultural specification with a cast iron sump making it particularly appealing for installation in a farm tractor. Thus the change of engine configuration of the world renowned Massey Ferguson 35 tractor, was an easy decision for the engineers and management of MF in the early 1960’s. The MF35 tractor fitted with the Perkins A3.l52 indirect injection diesel engine proved an immediate success. Results from users praising the outstanding performance resulted in long lead times for factory production to keep up with orders. Not only was this engine quite frugal on fuel consumption but was also a good starter in cold weather, provided a decent battery and inlet manifold heater plug were employed.

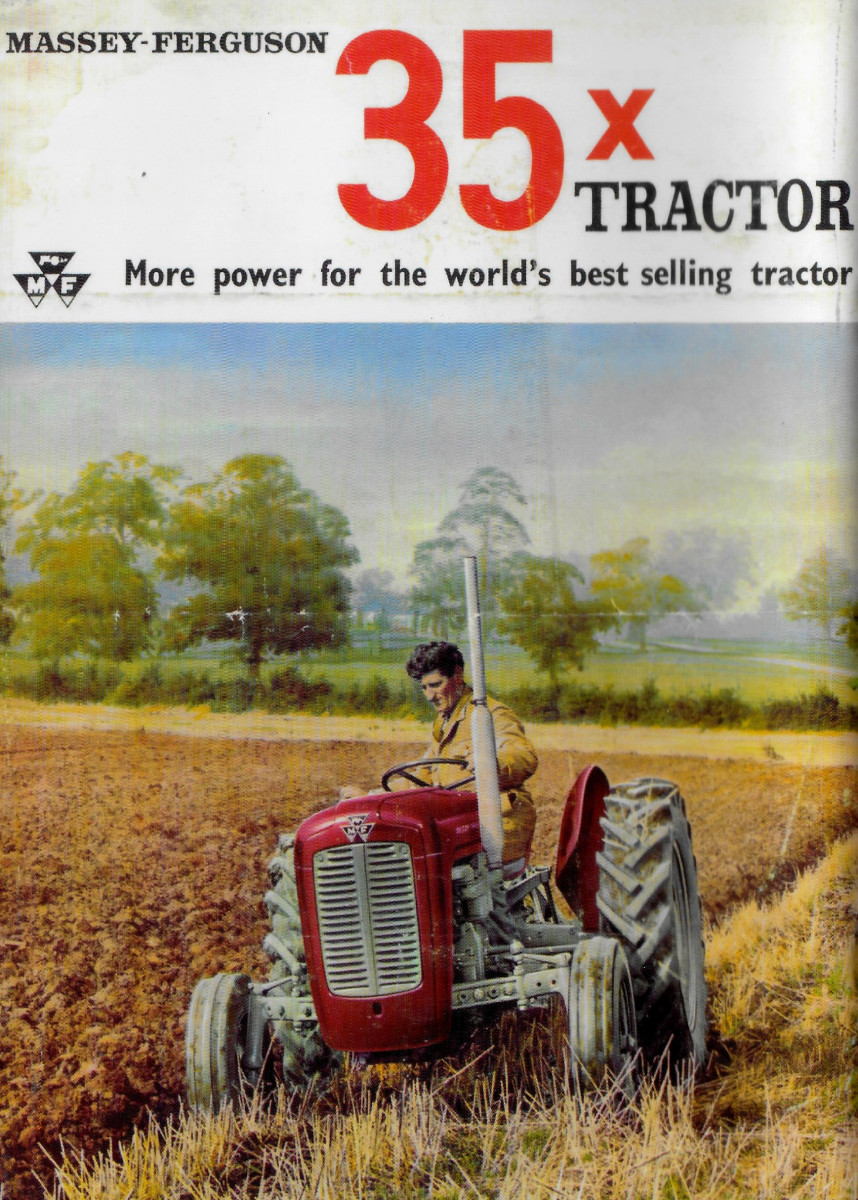

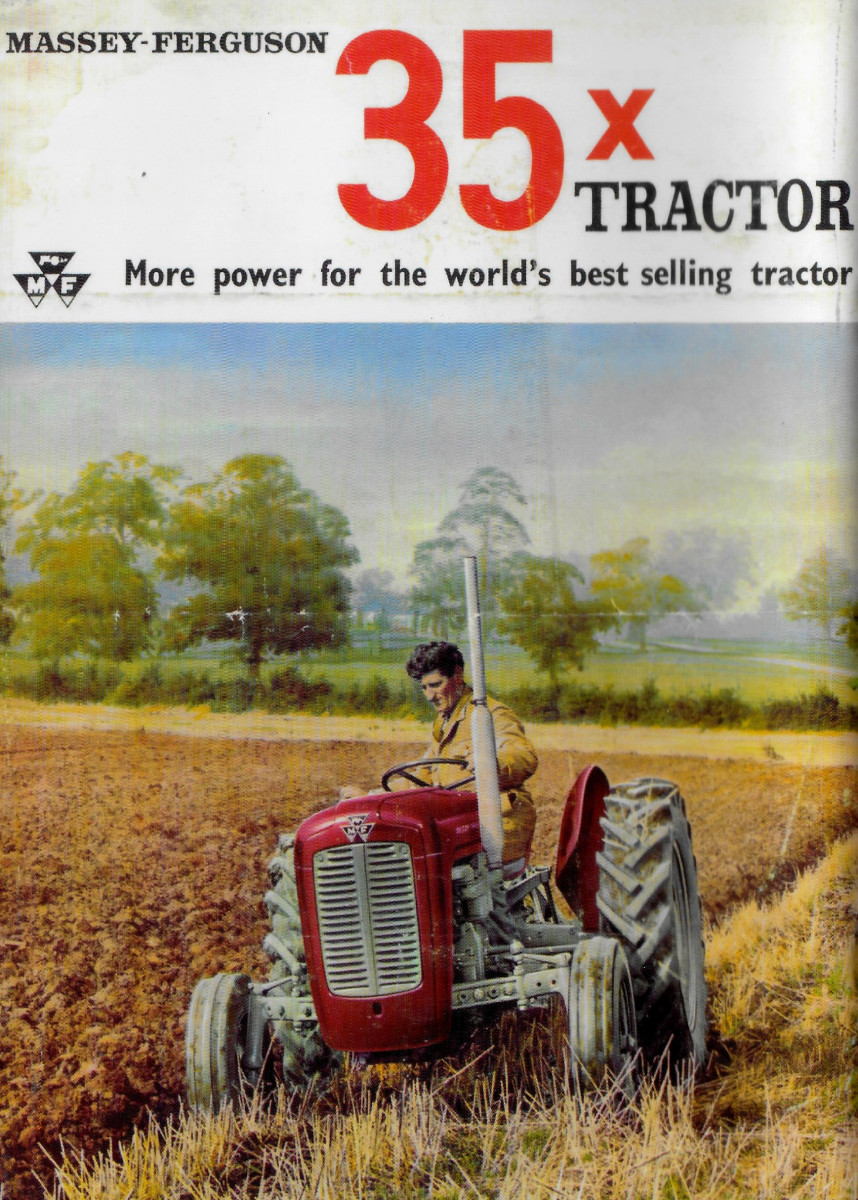

In mid 1962, the MF35 tractor at 39.6 engine horsepower became available with a differential lock as part of its optional equipment for all markets, powcr could either be by diesel, petrol or TVO (Vaporizing Oil) and both a single or dual clutch transmission could be specified. The demand for a higher horsepower on both the MF65 and 35 tractors resulted in the use of the Perkins AD4.203 engine in the larger model and a search for a suitable power unit for the MF35 tractor. Perkins engines could be specified to suit many customer and application requirements, such as a constant low revving engine for a water pump or generator and a higher revving engine for a commercial vehicle. The installation of the A3.l52 engine in the MF35 provided an excellent power to weight ratio and was proving to be a very reliable unit. MF Engineers seeking to improve performance even more, looked to Perkins for a different version of this popular engine. What evolved was a master stroke, by increasing the high idle (Perkins technical description) from 2000 rpm to 2250 rpm and the low idle (tick¬over) by 50 rpm together with some fuelling changes to the DPA fuel injection pump, the engine was now able to push out 44.5 hp without compromising reliability and a slight increase in torque to 119 Ibs./ft at a lowly 1300 rpm. The Massey Ferguson sales and marketing department needed to maximise visibility to this power increase, so to emphasise the Extra Power, the designa¬tion model numbering was changed to the MF 35X, with the ‘X’ signifying the letter x from the word extra. Benefits to this change were numerous, road speed increased by 2.5 mph in top gear, maximum power at the PTO went up by 4.2 hp from 37.3 to 41.5 proving the famous Ferguson System of minimum power loss at the PTO, with also maintaining the 540 rpm at 1500 rpm engine speed. When launched in the latter part of 1962, MF sales literature of the time boasted that the new engine provided ‘More power for the world’s best selling tractor’, with the newly improved diesel engine featuring a ‘combined direct and indirect fuel injection system for sure starting and clean burning for maximum fuel economy’.

Both the Basic and De Luxe versions were available for all markets, the Basic designation providing a single trans¬mission clutch for both diesel, petrol and v.O. power. The De Luxe specification for a standard width or Vineyard model included a dual clutch, tractormeter and cushion seat. Whilst the differential lock was now standard equipment in the UK, other markets could still specify a tractor without. Noticeably, the PAVT (power adjustable variable track) rear wheel specification now appeared in the list of factory options. It is important to note that only the diesel engine version was badged 35X, petrol and V.O. power maintaining just the MF35 nomenclature (often refurbished non diesel models appear to have the ‘X’ designation decals which is incorrect). Tyre option remained as previously with either crossply 4.00-19 or 6.00-16 fronts and 11.2/10-28 or 12.4/11-28 rears. The majority of MF35X tractors were specified with the larger tyres, export markets having a wider choice of rear tyres to suit their specific ground conditions.

In terms of performance, the MF35X was top of the class for its power to weight ratio, well out in front of all its competitors at 34.23 hp/ton (30.79 hp/tonne). Interestingly the MF65 Mark 11 virtually equalled this figure. Even today this matches and in some cases exceeds the figures produced by modern 200hp tractors. So enhancing the reputation of the 35X model as to its customer high acceptance then and as well as today – as a leading Classic tractor commanding high values in recent sales.

The Multi-Power change on the move transmission was first seen on a limited number of Massey Ferguson 50 tractors made in the North American Detroit factory. Successfully launched on the MF 65 tractor in 1962, it provided an overdrive for every manual gear selection without any break in transmission eliminating wheelspin. Its very low power consumption, using a hydraulic clutch pack, enhanced performance both at the wheels and PTO, making it suitable for lower horsepower tractors. Together with ‘HilI Hold’ in the high Multi-Power ratio and a welcome increase in road speed, it proved very popular as a fairly low cost option to provide 12 forward and 4 reverse gears; driver operation made simply by a dashboard mounted lever. Shortly after the launch of the MF35X, in December 1962 Multi-Power was available as a factory fit and detailed in price lists as a transmission option. It proved very popular and with the increase in PTO powered implements, enhanced field performance by matching forward speed to output.

The Multi-Power change on the move transmission was first seen on a limited number of Massey Ferguson 50 tractors made in the North American Detroit factory. Successfully launched on the MF 65 tractor in 1962, it provided an overdrive for every manual gear selection without any break in transmission eliminating wheelspin. Its very low power consumption, using a hydraulic clutch pack, enhanced performance both at the wheels and PTO, making it suitable for lower horsepower tractors. Together with ‘HilI Hold’ in the high Multi-Power ratio and a welcome increase in road speed, it proved very popular as a fairly low cost option to provide 12 forward and 4 reverse gears; driver operation made simply by a dashboard mounted lever. Shortly after the launch of the MF35X, in December 1962 Multi-Power was available as a factory fit and detailed in price lists as a transmission option. It proved very popular and with the increase in PTO powered implements, enhanced field performance by matching forward speed to output.

Subtle changes to specification of the MF35X tractor were made throughout its two year production run since it entered production on 8th November 1962 at Serial Number 302413. Later in 1963, to meet market and legislative changes, the shell type rear safety fender (mudguards) were factory fitted, necessitating a wider foot¬step to meet up with the extended fender. At the same time, the adjustable track front axle bolts were changed to 15/16″ AF from 1 1/16″ AF, suitable tools in the toolbox available to match, also a fan belt finger guard was attached to the dynamo.

Launch of the MF100 Series tractors in 1964 saw the MF35X replaced with the MF135 model, not many changes were made at this horsepower. The latest AD3.l52 direct injection engine was specified alongside the sheet metal of the 100 Series and PTO 540 rpm now running at 1700 rpm engine speed in line with all the 100 Series models. A two lever hydraulic quadrant with Pressure Control was now standard in the UK with Response control moved to the gearbox side cover, otherwise the basics of the MF35X were still utilised. However. as the MFI35 was destined to be the last model introduced on the factory production line. the MF35X continued alongside thc new MFI65 and 175 models. In fact, customers on a long waiting list for the new model were given the option of an MF35X instead at a small discount – thus new MF35X tractors appeared into 1965. For some northern European markets, due to Homologation legislation, the MF35X had a change of PTO constant mess gears such that the 540 PTO speed now came in at 1700 rpm engine speed to match the MF100 Series sold in these countries. This specifically due to the lack of availability of the new MFl35 model.

The Iconic status of the MF35X tractor encompassed the true design concepts of Harry Ferguson, having both simplicity with practicality similar to the TE20 tractor. It followed the FE35 and MF35 models in having a fully opening bonnet to assist easier servicing, the use of one type of oil in both the engine, gearbox, hydraulics and steering box, easily adjustable track settings without the use of special tools and very good access to the drivers ‘sit astride’ seating position where all controls fell easily to hand, making it compatible with a huge amount of implements for high work output. Quality of factory components and paint¬work, together with care in its construction from a dedicated workforce, have stood the test of time, with many examples of the MF35X tractor still at work around the world after 60 years since its introduction.

J Chris Clack, Journal 102 Autumn 2022

J Chris Clack, Journal 102 Autumn 2022

Published in Journal No.51, Winter 2005

Published in Journal No.51, Winter 2005