When Harry Ferguson developed his Ferguson System in the 1930’s, one of his main objectives was to make the integrated tractor and Implement as simple to use as it was efficient. An important part of this system was the ‘Ferguson Spanner’. Contrary to the popular opinion that this was for dipping the fuel tank, this spanner was designed to be a universal tool to facilitate the adjustment and servicing of the tractor and implement. The inch graduations on the stem were used to check the furrow width and depth, while the open ends fitted most of the nuts and bolts Ferguson used. The first version of the tool was supplied with the Ferguson Brown tractor and as the’ thread type David Brown used used Whitworth or BSF, the spanner was accordingly 5/8 x 7/16W. Along the stem was forged the ‘Ferguson’ script in relief. It is interesting that in the 1963 MF35 parts list, it still describes the spanner as being 7/16″ x 5/8″. When Ferguson linked up with Ford in the USA, the Ford Ferguson and the Sherman implements resulted. The screw threads from then on became American unified so the spanner now became 1 1/16 x 11/16 AF. .These spanners were made for Ford by the Manzel tool company and the ‘M’ within a circle logo was forrged on the reverse side of the stem, the front having the inch graduations. Manzel produced these’ spanners long after Ferguson and Ford pated company, each issue after the first being numbered from number 2 on to number 30. At number 9 the Ford logo along with the 9N17014 part number appeared on the face and in 1948 at number 13, the FOMOCO logo was used. These were’ supplied with the 8N on into the 50’s. When Ferguson returned to England and Standard Motors started production at Banner Lane the spanner supplied at first had only inches on the face, sometimes with a Staffordshire knot on the reverse. The basic design more or less remained unchanged only with slight forging variation, EN5C and EN18 (Steel grade numbers) appearing in various positions, until around 1970 when the ‘girder’ stem was introduced. Variations on this design had ‘Made in England’, ‘Made in Germany’ and ‘Made in France’ forged on them. Around 1968 the practice of supplying a spanner with every new tractor ceased and became accessories which could be purchased from the dealer. Matching ring spanners were produced by Britool, Birdsall and Vapormatic, which were used mainly by mechanics. Sparex produced a copy of the open ender and Kvernland supplied a lookalike with the ploughs in the 1960’s. In the USA, Ferguson supplied various wrenches starting with an open ender with Harry Ferguson INC and the part number T017014 on the stem. The toolmaker must have been hungover on more than one occasion because some of these had mistakes on them such as letters missing out of ‘Harry’ and the ‘S’ printed in reverse, these tools were normally galvanised. The next version had Ferguson stamped into the 1 1/16″ end, and TO17014 stamped into the 11/16″ end. The ‘TO’ in the part number identified the item as ‘Tractor Overseas’, as opposed to ‘TE’, ‘Tractor England’. With the merger with Massey Harris the design featured the MHF logo and the new Massey Harris part number 180 108M 1 forged on the stem. again these were galvanised. One of the unusual spanners I have in my collection has MASSEY FERGUSON forged on the stem with centimetres on the reverse. I don’t know the origin of this one but I guess it could be South American. Any info would be appreciated. In this article I can only give a brief insight into this legendary tool and with over 80 versions in my collection and still looking for others I have more to learn on the subject. Just to end, when the wreckers were scrapping the Banner Lane factory one of the stillages which got tipped into the scrap skips contained over a ton of brand new Fergie spanners! Reprinted in Journal 109, Summer 2024

Harry Ferguson

Mrs Elizabeth Sheldon (1920 – 1997)

Born Elizabeth Ferguson in Belfast in 1920, where she attended school until the age of 14 when her father decided that any further education would be best obtained in the big wide world. Consequently she spent much of her time travelling the world accompanying her father on his many trips particually to America.

It was in America that one of the many amusing stories of her life happened. One particular day Harry Ferguson was entertaining Henry Ford and Elizabeth was sent to make a pot of tea. Unfortunately she could not work out how the new fangled electric kettle worked and knowing that her father was intolerant of failure was beginning to panic. After some time Elizabeth relented and returned to the meeting room to summon help, both Harry and Henry Ford, two of the greatest engineers that the world has known could not get the kettle to boil also. “Well” said Harry “lets forget about having tea Mr Ford has to return to his office, we will detain him no longer”.

After the war Elizabeth spent some time in France where she attended the Sorbonne and helped set up Harry Ferguson France. Elizabeth spoke french fluently and played tennis with distinction and rode when time allowed with the Cotswold Hunt.

Elizabeth married Tony Sheldon in 1950 they lived near to Abbotswood in Stow on Wold as Tony worked for Ferguson Research after its formation. They moved to the Isle of Wight in 1970 where she enjoyed, with Tony, many hours sailing, supporting him when he was Commodore of the Royal Yacht Squadron at Cowes. She continued to represent the memory of her father and his engineering achievements through Harry Ferguson Holdings and Ferguson Research. She was of course Patron of the Ferguson Club.

Mrs. Sheldon was respected by everyone who met her and made one feel ‘at home’, she had a great sense of humour. She is survived by Tony, has a son Jamie, two daughters Caroline and Sally and five grandchildren.

Duncan Russell

Books written and published about Harry Ferguson

A Compilation of books written and published about Harry Ferguson,

Ferguson, Massey Harris and Massey Ferguson;

“I would like to thank Alan Condie, John Farnworth and Peter Drinkwater for their contribution in helping me put this list together. Mike Thorne.”

Compiled and validated to the best of their knowledge, on behalf of The Ferguson Club

© The Ferguson Club August 2021

This list is not definitive and the Ferguson Club would welcome additions or edits to what we have presented here – please let the website editor know of updates

- A Global Corporation by EP Neufeld ; 1969 ; University Press of Toronto ; 427 pages

- Harry Ferguson Inventor and Pioneer by Colin Fraser ; 1972 ; John Murray publishing ; hardback ; republished by Old Pond ; paperback 1998 ; 288 pages ; ISBN 0-9533651-2-3

A list of books by John Farnworth

- Ferguson Implements and Accessories ; revised edition 2006 ; Japonica Press ; 223 pages ISBN 1-904686-08-7

- Massey Legacy Vol I ; 1997 ; Farming Press ; 399 pages, ISBN 0-85263-403

- Massey Legacy Vol II ; 1998 ; Farming Press ; 272 pages, ISBN 0-85236-404-0

- Advertising of Massey Harris, Ferguson and Massey Ferguson ; 1999 ; Farming Press ; 320 pages, ISBN 0-85236-528-4

- The MF500 Tractor Era ; 2010 ; Japonica Press ; 271 pages, ISBN 978-1-904-686

- Massey Ferguson 100 and 1000 Tractors ; 2003 ; Japonica Press ; 323 pages, ISBN 1-90468-05-2

- A Worldwide Massey Ferguson Industrial & Construction Equipment ; 2001 ; Japonica Press ; 309 pages ; ISBN 0-9540222-0-3

- A Worldwide Guide to Massey Harris, Ferguson and early Massey Harris Ferguson tractors ; 2000 ; Japonica Press ; 239 pages ; ISBN 09533737-6-2

- Memories of the Founding of Massey Ferguson, 1953-1958 ; 2007 ; Japonica Press ; 223 pages ; ISBN 1-9 04686-14-19

- Massey Harris Harvesters ; 2013 ; Japonica Press ; 339 pages ; ISBN 978-1-904686-32-3

- Ferguson, The Hunday Experience ; 2000 ; Japonica Press ; 378 pages ; ISBN 09533737-5-4

- Ferguson Advertising ; 2014 ; Herridge & Sons ; 144 pages ; ISBN 978-1-906733-62-7

- Working with Harry Ferguson ; 2017 ; Japonica Press ; 144 pages ;

- Early Massey Ferguson Implements ; 2019 ; Japonica Press ; 281 pages ; ISBN 978-1-904686-97-2

John’s (Farnworth) Personal Publications

- The Farnworth Masseys ; 2004 ; A substantial booklet of 41 pages – (out of print)

- The Evolution of Massey Ferguson Training ; A substantial booklet of 82 pages

A list of books by Alan Condie – Published by Alan Condie

- The Ferguson Album ; 1st published 1990 – reprinted 1993 ; ISBN 0-907742-82-3 (hardback) ISBN 0-907742-83-1 (softback)

- The Fergie 20 Family Vintage Tractor Special ; 1st published 1992 – reprinted 1995,1998,2001 ; 64 pages ; A4 saddle stitched ; ISBN 0-907742-59-9

- Fergie 20 Implements, Accessories and Industrial Equipment. Vintage Tractor Special No.2 ; 1st published 1996 – reprinted 2002 ; 48 pages ; A4 saddle stitiched ; ISBN 1-85638-006-8

- Massey Ferguson 1958-82 Classic Tractor Special No.3 ; 1st published 1995 – reprinted 2002 ; 56 pages ; A4 saddle stitched ; ISBN 0-907742-92-0

- By Alan Condie but published by Midland Counties Publications ; Great Tractor Builders, Ferguson ; 2001 ; 96 pages ; Quarto printed paper case ; ISBN 97807-1102-8265

Other Authors

- The Ferguson Story ; Stuart Gibbard ; Old Pond ; 2000 ; 168 pages ; ISBN 1-903366-08-9

- Living Biographies, Harry Ferguson by Norman Wymer ; 1961 ; Phoenix House Ltd.

- Harry Ferguson ; Bill Martin ; Ulster Folk & Transport Museum ; 30 pages ; Landscape Format ; soft back

- Ferguson, a Farming Revolution ; Tim Bolton ; 114 pages ; softback ; Morton Books ; 2021 ; ISBN 978-1-911658-22-1

- Working at Masseys by Ken Tyrell ; 213 pages ; Bread Book ; 2008 ; paperback ; ISBN 0-09542112-7-8

- Inside Massey Ferguson – A Story of Service ; David Walker ; Farm Power Publishing ; 2011 ; 265 pages ; softback

- Harry Ferguson Before the Plough ; Michael Clarke in collaboration with Jack Woods ; 159 pages ; Ballyhay Books, an imprint of Laurel Cottage Books ; 57 pages ; softback ; 2009

- The Standard Motor Company ; Graham Robson ; Veloce Publishing ; 2011 ; 208 pages ; ISBN 1-845843-43-4

- Not strictly a book about Ferguson but a lot of insight into the man Harry Ferguson. ; To Make a Better Mousetrap ; a biography of Rex McCandless by R.L Jennings ; self published 2003, revised 2011 ; hardback ; 265 pages ; ISBN 978-0-9534628-4-1

- Traction For Sale ; Bill Munro & Pat Turner ; Earlswood Press ; 2019 ; 298 pages ; ISBN 9780993101861 ; A substantial book about the evolution of Formula Ferguson 4wd Systems

- Harry Ferguson, A Brief History of his Life and Tractors ; Massey Ferguson Tractors Ltd ; 1986 ; publication no. 1856772 M1

- The Massey Ferguson Workshop Service Manual ; Chris Jaworski ; Old Pond Publishing ; 2013 ; 206 pages ; ISBN 978-1-908397-12-6

- Massey Ferguson Tractors ; Michael Williams ; 1987 ; Blandford Press ; 128 pages ; ISBN 0-7137-1898-6

- Massey Ferguson Tractors ; Michael Williams ; 2005 ; Bounty Books ; ISBN 0-7537-1144-3 or ISBN 13-978753711446

- Massey Ferguson Tractors ; Michael Williams ; 1989 ; ISBN 0-85236-203-x (13, 14 & 15 above are the same books)

- The Big Book of Massey Ferguson Tractors ; The Complete Book of Massey Harris & Massey Ferguson Tractors, Collectibles, Sales Memorabilia and Brochures ; Robert Pripps ; 2006 ; ISBN 076032655x

- Ferguson, The Story Continues, an Illustrated History ; Max Smith ; AGCO ; 1998 No. 12720-0398

- Sixty Years of FE35 Tractor ; Stevan DT Patterson ;

- Seventy Years of The Ferguson TE20 ; Stevan DT Patterson

- The Ford Ferguson Tractor ; Stevan DT Patterson

- The Ferguson Black Tractor by Stevan DT Patterson

- Eighty Years of the Ferguson Brown Type A and Black Tractor ; Stevan DT Patterson

- Peter and Pauline at Hollyhock Farm ; RAE Linney ; originally published in 1951 by Harry Ferguson Ltd ; republished in 2008 ; Old Pond ; a charming childrens book about the Ferguson TE20 ; 48 pages ; hardback ; ISBN 978-1-905523-94-8

- Harry Ferguson and I ; Michael Winter (HF Personal Assistant) ; self published 1995 ; paperback ; A5 ; 135 pages

- The Legendary LTX Tractor, The Big Fergie Story ; M Thorne published in 2000 ; originally included with a limited run of 1/18th scale models of the LTX

- A Rural Revolution ; J Wentworth Day ; a Harry Ferguson publication ; 1952 ; 115 pages ; softback – RARE

- British Tractors by Stuart Gibbard ; Herridge & Sons Ltd ; 2013 ; ISBN 978-1-906-133-52-8 ; Covers a lot of makes but a good chunk on Ferguson

- Ferguson TE20 Tractor 1946 Onwards, The Enthusiasts Manual ; Haynes Ltd ; ISBN 9780-85733-01-09 – currently out of print

- TE20 In Detail ; Michael Thorne ; Herridge & Sons Ltd ; 2006 ; 174 pages ; hardback ; phots by Andrew Morland ; ISBN 978-0-9549981-3-4

- Massey Ferguson 35/65 In Detail ; Michael Thorne ; Herridge & Sons Ltd ; 2014 ; photos by Andrew Morland ; ISBN 978-1-906133-53-5

- Massey Ferguson 100 Series In Detail ; Michael Thorne ; Herridge & Sons Ltd ; 2017 ; hardback ; photos by Andrew Morland ; ISBN 978-1-906133-76-4

- Massey Ferguson Tractors ; Jonathan Whitlam ; ISBN 9781445667256

© The Ferguson Club August 2021

Harry Ferguson’s Rolls-Royces and Bentleys

Born in 1884 into a farming family, Ulsterman Harry Ferguson became interested in cars from the time that cars first began to appear on British roads. Though he had planned to emigrate to Canada to escape the severe discipline that his very religious father imposed upon the entire family, his elder brother Joe invited him to work for him in the garage he had set up in Belfast. Harry seized the opportunity and in 1911 he set up his own garage, May Street Motors in Belfast. He competed in motor sport events and as he was an agent for Vauxhall cars, was given the chance to drive a works Vauxhall CType. Unfortunately, he crashed it and with it went his chances of any further drives for the company.

During the 1920’s, Harry Ferguson held the Austin dealership for Belfast and one of his private cars was a 1929 Austin 12/4 with a fabric saloon body. Though most cars at this time would have been finished in a dark colour, Harry Ferguson was bucking the trend with this car, as the picture is captioned ‘the first all-cream car’.

Harry Ferguson’s personal car, a 1929 fabric-bodied Austin 12/4, in what was then a most unusual cream colour.

Ferguson Family Museum/Sam Scadgell

We have no details of what cars he may have had when he and his wife, Maureen moved to Yorkshire when the Ferguson-Brown tractor was being built, but we do know that he enjoyed the privileges that his new wealth brought, which included retaining a butler. Maureen Ferguson never learned to drive, so Harry may have retained a chauffeur to drive her around when he was out on business. It wouldn’t be a stretch of the imagination to think that, as his income grew, he developed a taste for quality cars. In the years immediately prior to the Second World War and through the war years, the Fergusons were domiciled in the USA. Again, we have no idea of exactly what cars he may have owned or had at his disposal, but considering his connections with the Ford Motor Company, some may have been Lincolns, Ford’s luxury brand.

It’s only from when Harry Ferguson acquired the Abbotswood Estate in 1946 that we know about the cars he bought and enjoyed. One maker, Rolls-Royce was his clear favourite. The first car he bought on his return to Britain, in August 1946 was a pre-war Rolls-Royce Phantom III, the first of six Rolls-Royces or Bentleys he bought post-war. This may well have come from London Rolls-Royce and Bentley dealers Jack Barclay, as a picture of such a car appears in one of many Rolls-Royce book carrying the caption ‘Jack Barclay Ltd’. Dating from the late 1930’s, this Phantom III had a swept-tail sports saloon body by Barker. A photograph of him standing by the passenger door can be found in Colin Fraser’s biography of Harry Ferguson.

Ferguson had wanted a new car, but in the immediate aftermath of the Second World War, new cars were very difficult to acquire on the home market, as the government demanded that as many cars be exported as possible to recoup the huge sums spent on fighting the war. Used cars of any description were also hard to find and fetched ridiculously high prices, regardless of condition, but Ferguson may have had some good connections in obtaining the Phantom; either that or Jack Barclay was struggling to sell such a large, thirsty car (it had a 7.3 litre V12 engine) in a time of severe petrol rationing.

Nevertheless, he bought the Phantom and at the same time, placed an order with Barclay for a new Bentley MkVI. This was one of Rolls-Royce’s two new models, (Rolls-Royce bought Bentley in 1931) the other being the more expensive Silver Wraith. A radical departure for Rolls-Royce was that the MkVI and its slightly later sister car, the Rolls-Royce Silver Dawn had a new all-steel 4-door saloon body, made at Cowley by the Pressed Steel Company.

Harry Ferguson steps out of his first new car after the Second World War, a Bentley MkVI Standard Steel saloon. Ferguson Family Museum/Sam Scadgell

Though the majority of these bodies, known as the Standard Steel Saloon, were trimmed at Rolls-Royce’s new Derby factory, Harry Ferguson’s example was painted and trimmed by Bromley, Kent coachbuilder, James Young, which had been acquired by Jack Barclay in 1937. Rolls-Royce expert Tom Clarke told me that the factory in Derby, where the new cars were being made, was having great difficulty trimming the new steel bodies. Tom also suggested to me that Ferguson may have struck up a good working relationship with James Young’s manager and chief designer, A.F. ‘Mac’ McNeil, as the name of James Young will appear again in this story.

The car, JLX 73 was finished in black and was ready for delivery in Spring, 1948 a year and a half from him ordering it. However, Ferguson’s ownership of it began with a rather unfortunate incident. Michael Winter, who served as Harry Ferguson’s personal assistant between 1947 and 1954, wrote of the matter in his 1995 book, Harry Ferguson and Me (selfpublished in 1995). The Ferguson family were in France at this time, where Harry Ferguson was visiting his French subsidiary, ahead of a holiday in Provence. Winter acted as Ferguson’s chauffeur when the regular chauffeur was driving Mrs. Ferguson and he was instructed to collect the car from Jack Barclay and take it across the Channel. He was met off the ferry at Boulogne by the French subsidiary’s Managing Director and, as was the custom, they stopped on the way for what can best be described as a ‘very good lunch’. When Winter arrived in Paris, the effects of the lunch were beginning to take their toll and, sleepy from the wine and confused by the Paris traffic, he wrapped the Bentley around a lamppost. Ferguson was furious, especially as he had waited so long for it to arrive and he told Winter bluntly that this incident put his job in great jeopardy. Fortunately for Winter, Ferguson relented and kept him on. Winter does not say whether the family continued with their holiday, but if they had not, Mrs. Ferguson would have not been at all pleased, as, since they had moved to Abbotswood, she was continually trying to get her husband to cut down on his workload! Incidentally, around this time, Ferguson was filmed outside the offices of the tractor factory in Coventry, getting out of the driver’s side of a Triumph 1800 saloon. Whether he had bought the car, or if he had been either given or loaned it by Sir John Black, the boss of Standard’s, we don’t know. In any case, we know that Ferguson’s eyesight was troubling him and as a result he rarely drove, so it may have been a posed shot. But Harry Ferguson, it seems found riding in cars, or indeed sitting down for any length of time, troublesome. He had suffered chronic back pain since he crashed his aeroplane back in 1911. The Ferguson Family Museum displays an item that Harry Ferguson used whenever he was sitting. It is a small, padded seat, known as his ‘Throne’, which he used to ease his discomfort.

Harry Ferguson is standing next to his second Bentley the 1950 gunmetal standard steel saloon MkVI. Ferguson Family Museum/Sam Scadgell

In 1950, Ferguson bought a second Standard Steel Bentley MVII, LLD 703, finished in gunmetal metallic paint. James Young’s name reappears in connection with Ferguson’s third Bentley MkVI, MLY 28, which, rather than the steel body, had a 6-light coachbuilt saloon body by James Young. This he bought in 1952 and it may be that the Phantom was taken in part exchange for this car.

Harry Ferguson’s first new Rolls-Royce, postwar, was this 1954 Silver Wraith, with a James Young body. Tom Clarke

In 1954 he bought his first new Rolls-Royce. This was a Silver Wraith, OLM 98 and, like MLY 28 also had a James Young saloon body, finished in silver but of a somewhat more modern style. Peter Warr recalls Ferguson’s penultimate Rolls- Royce, which was bought in 1955. It was another Silver Wraith saloon, registration number RXY 618 and Ferguson’s third car with a James Young saloon body. This had similar lines to MLY 28, but it was finished in black.

Harry Ferguson is next to his second Silver Wraith which was a long-wheelbase James Young saloon, known as the ‘five houses’ car. Location: Little Donegal St., Belfast. The building in the background with the curved frontage is the site of the garage that belonged to Harry Ferguson’s brother, Joe. (Tom Clarke)

Peter Warr recalls this car clearly, saying: “It was a very expensive car, which we nicknamed ‘five houses’, because that’s what the price of the car would have bought! Unfortunately, the car made Mrs. Ferguson travel sick, so she couldn’t ride in it. Harry Ferguson said that this was sad, because having worked so hard to earn the kind of money he was earning, his wife could not enjoy the benefits.” He took the car to Belfast on at least one occasion. It still exists, but has been repainted in maroon.

He wanted to replace RXY 618 fairly soon, but could not take delivery of a new car to replace it in a short period of time, so he bought a second-hand 1955 Rolls-Royce Silver Dawn, registration number PXD 94, with, yet again a James Young saloon body. The original owner was Belfast ship owner H. P. Lenaghan & Son and Ferguson may possibly have done business with them. This is the last of the Rolls-Royces and Bentleys that Harry Ferguson owned that we know of.

Thanks to Peter and Ann Warr and Tom Clarke for their help in producing this article.

Published in Journal No. 109 Summer 2024, Bill Munro

The Ferguson

Approach to Education

Copy of an early letter from Dick Chambers (circa.1951)

APPROACH TO EDUCATION

Distributors are well aware of the importance attached to education as applied to the Ferguson franchise, and it is considered desirable at this stage to review the situation and point out how Distributors may gain the full benefit from an Education Scheme in their own territory, and so build a very prosperous future for their Ferguson franchise.

Value of Education

We have no doubt whatever that through the Education Plan as applied by Harry Ferguson Limited, Coventry, the sales of Ferguson products have been considerably higher than would have been possible without instruction being given to Salesmen and Servicemen in the proper adjustment and use of the equipment. Just how much the very large volume of business being enjoyed by this Company can be attributed to education, is certainly a matter for conjecture. We do know, however, that most of the sales are made by what the implement does. We have a maxim “It is what the implement does that sells the tractors”.

We do not propose to burden this article with the many experiences which can be quoted how proper adjustment of the implement and proper appreciation of the Ferguson System, and what is built into it, has enabled salesmen to prove to the Farmers that the equipment is suitable for their requirements.

The value of education is exemplified in so many ways that we feel the quoting of just one example may be permitted. Experience has shown that where the Agricultural Mower has been properly understood by the salesmen and demonstrators of a dealer, who, in turn have passed this information on as completely as possible to the owners, the satisfaction obtained by these owners from this piece of equipment has been very much more than where the Dealers’ Salesmen and Servicemen were unfamiliar with the equipment, and, therefore unable to instruct the owners.

Please understand that this is only one example, we can quote many more.

What To Do

It is our desire to help all Distributors in the Education Scheme, and any help that this Company can give is at the disposal of all distributors.

It is our view that each Distributor should immediately set up an efficient Education Organisation, the staff of which would devote their whole time to instruction. The primary object of this Department would be dissemination of instruction on Ferguson equipment to representatives of Dealers and Sub-Dealers, so that they would have a fuller ability to demonstrate the equipment successfully, maintain it correctly and gain a precise appreciation of the aims of the Ferguson Plan and System.

We suggest that your instruction should not be limited to the Dealer Organisation. We have, in fact, through or Coventry Education Department been extremely successful in spreading the information on the Ferguson System far and wide through the medium of other Organisations. In this connection, the Government Agricultural Advisory Officers form a useful nucleus through which information may be passed to farmers. It is of course, essential that these Agricultural Advisors should be well briefed in the equipment and the plan behind the production of this modern agricultural machinery. There is no doubt that the easiest way, and the most lasting way to convince Agricultural Advisors, is through practical experience with the equipment.

To fulfil this, we have arranged a number of very successful courses, each lasting about one week, to which the Agricultural Advisors have been invited. We know that, if we may coin a word, these Advisors have been “Fergusonised” during their stay with us. They, in turn, speak highly of the equipment when amongst farmers, and, in fact, become unpaid salesmen.

We have arranged other courses for Agricultural representatives of the various Rubber Companies, and similar courses for the Oil Companies Agricultural Representatives.

It is agreed that the Agricultural Advisors and Agricultural Representatives must not become too biased towards our equipment, thus excluding completely from their minds other competitive equipment, but we do know from experience that these men have spoken very highly of our System and have often – perhaps unwittingly – swayed a doubtful prospect very much in our favour.

We submit that as well as the training of Sales and Service Representatives, the Managers of your various Dealers; these are other useful lines, which can be applied to an Education Department.

In addition, the Young Farmers’ Club Organisation members in England and Wales have completed, with us, a number of short term, usually weekend, courses on the equipment. We assist in the Young Farmers’ evening lectures, and visit various Agricultural colleges and Agricultural Institutes, with a view to explaining fully the principles behind the Organisation and how the Ferguson System works.

Our Education Scheme is opened to many non-agricultural organisations also – associations of businessmen like the Rotary Club, political bodies, etc., come under our barrage of Ferguson Plan and System propaganda by lectures and films. Distinct from the sales talks, these are of a general nature, aimed at selling the idea of more food at less cost.

For education of any type, one must take a long view, and not hope for immediate results, but it is gratifying to note that in Great Britain during the month of January 1951, we had 67% of the sales for all makes of wheeled agricultural tractors on the home market.

The education tree we have been growing during the past five years is now beginning to bear full fruit.

How To Do It

The setting up of an Education Department is something, which should receive the immediate attention of the Principals of your Company. There must be ample scope for the development of a first rate Education Scheme covering the territory for which you have a franchise. We do not wish to lay down any hard and fast rules for the establishment of an Education Department. We appreciate that each territory must have its own requirements, and its own suitable arrangements, but we feel that an indication of what can be done should be given to you so that the benefit of education to your Organisation, and, indeed, to the owners of the equipment, should be achieved at the earliest possible time.

Distributors have in the past sent representatives to our Instruction School established at Coventry, and here we should like to assure you that further visits from your staff will be welcome at any time.

The Education Department now has its own residential accommodation and lecture rooms right on the farm. The instruction is essentially of a practical nature, and two distinct types of course are arranged.

For the Field Course, instruction is given on the operation and the farm maintenance of the tractor and the adjustments necessary on the equipment, to obtain from that equipment the many features built into it. This course lasts for two weeks, and provides a useful basis on which salesmen may develop their knowledge of the Ferguson equipment. We do not claim that one such course completes the knowledge of our students in the Ferguson equipment, indeed, it is one of the features of the Ferguson franchise that for those who will keep an open mind, there is always more to learn. Overseas students are recommended to remain for two or three field courses, which enables them to become more familiar with the equipment, visit some of our home dealer organisations and gain experience in our office organisation.

For this course we run a fleet of 22 tractors, and a full range of equipment; Ploughs, Cultivators, and other basic implements being held in triplicate or more, so that each student is given an opportunity of operating the equipment in the field. It cannot be too strongly emphasised that during this course we teach “The System”, so that students are conversant with the range of equipment which will enable them to pass on to prospective customers details, which will eventually result in the prospect buying more of our range.

The Service course is designed primarily for Workshop Servicemen, whose job it is to ensure that the Ferguson equipment is maintained in top quality condition, so that the farmers in turn may derive the full benefit from it. During the Service Course students are given instruction by Departmental Managers and their Deputies of the Demonstration, Service, Sales and Spare Parts Departments of the Headquarters.

Residential accommodation expenses are paid by the students or their employers. All other expenses are charged against the general Company expenditure.

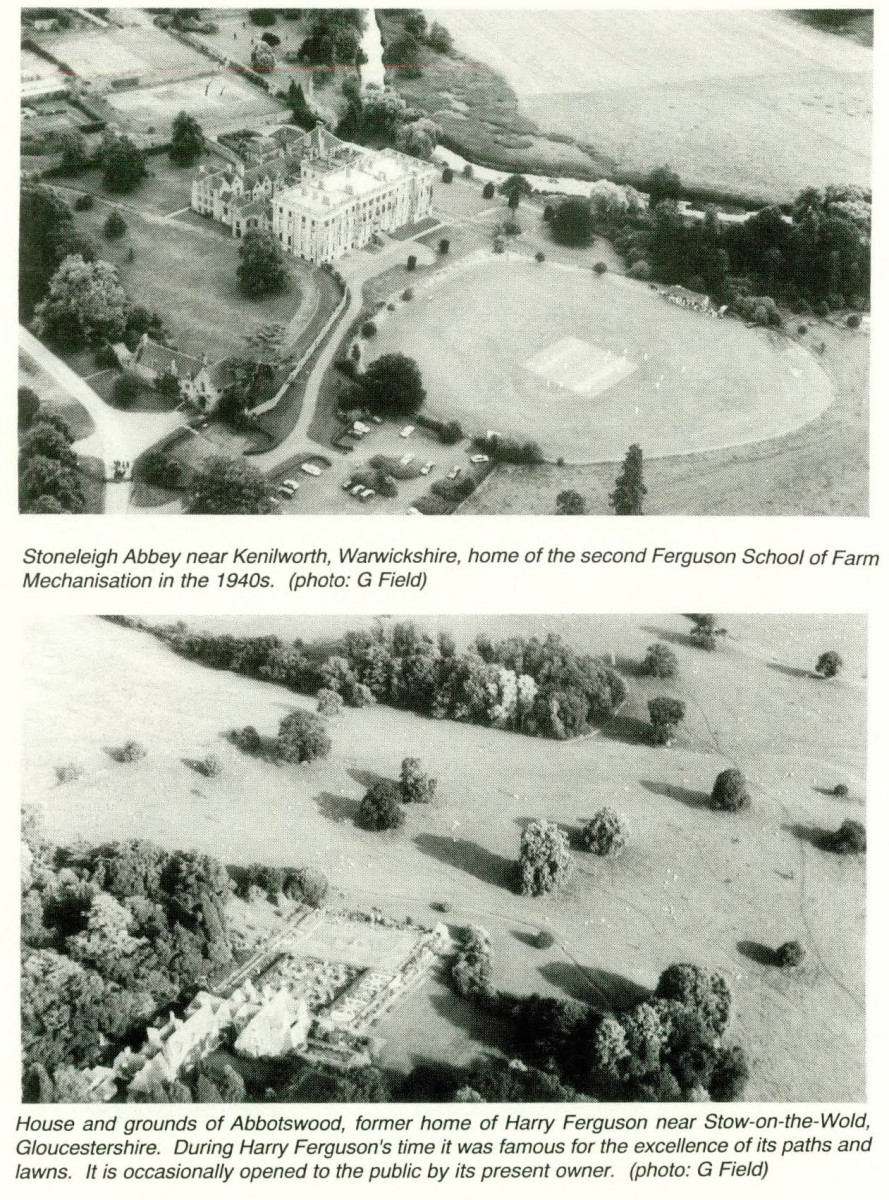

The ideal to be aimed at is something along the lines briefly indicated above, an, indeed we hope that when the equipment is being established in any country, due consideration will be given to the organisation of an Education Department along these lines. Much thought has been given to the organisation of the Department, and we always agree that the residential facilities are of very great importance in creating a friendship between representatives who will thereby have a full realisation of the importance of the Ferguson franchise, and understanding of the immensity of the Organisation. It is interesting to recall that on a recent course at our Residential School at Stoneleigh Abbey, 12 different nationalities were represented.

Even if it is not possible in the first year or so of holding a franchise, for a Distributor to set up a Residential Establishment, education should be given considerable priority in the Organisation. A few suggestions on how this may be achieved are submitted for your consideration.

One country starting with a nucleus of two representatives who were fully trained at our Coventry School, arranged for these representatives to visit each Dealer’s area in turn, and there to give practical instruction in the use of the equipment, to the Dealer’s Representatives. This team visited an area for a period of about two weeks, taking with them such equipment as was then available on which instruction could be given. The team moved on from Dealer to Dealer. In additional to equipping the Dealer’s Representatives with a full knowledge of the Ferguson System, they have made use of their time in the particular area to assist the local owners in any operation problems, which they may have had.

In this connection the presence of the team in an area enabled the local Dealer to arrange for a “Dealer Owner Meeting”, to which all owners and some of the more prominent prospects were invited. The Dealer meetings should be arranged in conjunction with a show of recent Ferguson films and the ensuing discussion has always enabled the Education Staff to get to know the problems of the Ferguson owners, and has enabled them to suggest methods of operating the tractor and equipment to achieve the results required by the farmers. So successful has this scheme been that the particular country concerned now has four prominent members of the Staff on Education. After the initial course has been held in each dealer’s area, further courses, specialising in newer equipment and revising on the old, are continually in operation.

Another country, having laboured hard and well in publicising the equipment and making good sales, has now come to realise that the establishment of a Ferguson Training School would be of more value from the publicity angle and of immense value to the owners, than any other system yet conceived. A Training School has therefore been established, and to this School will be invited all who in any way are connected with the Ferguson business, and also those other representatives of Organisations whose interests are in the Ferguson equipment.

Other countries have, in an endeavour to gain more information on the equipment, arranged to have a large number of Dealer’s representatives attend courses of instruction at our Residential School. We welcome the idea, but while good, we can only consider this as being a preliminary to the setting up of a successful Education Department in the Organisation concerned, and it is, in fact, noteworthy that such has been the case.

It is our intention to arrange from time to time for our Senior Instructors to visit Distributors and to assist them with advice on setting up of Education Departments. We feel certain that with the experience we have had during the past five years of education in this growing organisation, our Instructors could be of immense value to you. We are certain also that this intimate contact between your organisation and ours would be of real value in our appreciation of your agricultural conditions, and no doubt our staff would be very heartily welcomed by you.

In acknowledging receipt of this letter, please let us know what scheme of education you have covering your territory, and also whether we can be of further assistance to you in the immediate future prior to one of our staff visiting you.

We look forward with interest to your remarks.

Yours faithfully

For HARRY FERGUSON LIMITED

R M CHAMBERS, EDUCATION MANAGER.

The Development of Mechanised Farming

The Development of Mechanised Farming

One of a series of articles by Mike Thorne, with particular reference to the role of Harry Ferguson

The development of mechanised farming goes back to mankind’s earliest days, for it started when he first used a stick to scratch the soil instead of his own two hands. He domesticated animals and crops. Our present day cereals and livestock are man’s creation and in fact are entirely dependent upon man for survival. In turn, man depends on these creations for his own subsistence.

This process has gone on throughout the ages in an attempt to remove the threat of hunger and famine – this threat is still the driving force behind our efforts to raise the world’s standards of food production (and distribution). We all live on a knife- edge there is no such thing as a surplus of food in the world.

Each step upward in civilisation has meant an increased need for food and today there is still a very real prediction of hunger in much of the world.

As we have become much more civilised with the better hygiene and medicine. This need for more food, has increased more rapidly resulting in the enormous advances in the past century, particularly in new species and varieties of crops, livestock breeding, the introduction of artificial (so called) fertilisers and chemical sprays, pesticides of all kinds and the invention of a host of different farm machines.

It is only during the past 40 years that the horse has lost its pride of place as the power unit on our farms – using oats as its main source of fuel.

The change however, was a long and gradual one commencing in the early days of the industrial revolution with its driving force of the great invention that transformed the world-steam power (since which, science has learned more from the steam engine than the steam engine has learned from science).

The change however, was a long and gradual one commencing in the early days of the industrial revolution with its driving force of the great invention that transformed the world-steam power (since which, science has learned more from the steam engine than the steam engine has learned from science).

The larger and leading farmers were quick to adopt steam power for threshing and ploughing and some farsighted ones even suggested “that it might displace the horse in future”. However, the death knell of steam power was quickly sounded at about the time of World War I when the motor (I.C.) engine tractor was introduced into this country in comparatively large numbers.

The advantages of these machines over steam engines (or fire engines as they were called which were powerful but heavy and cumbersome) were quickly realised.

The period after the war still saw many horses at work and agriculture entered into the crippling depression of the early Thirties. It also put many manufacturers of farm machinery out of business, some good machines and some brilliant ideas went on the scrap heap, but so did much rubbish.

It is a strange thing, but farmers and churchmen were predominant in looking for ways and means. Jethro Tull was an example, the father of the seed drill and the system of row crop cultivation. The Rev. Patrick Bell gave us the reaper. Appleby the binder knotter and McCommick – self binder. Henry Ford a poor self- educated man and many others are just a few examples.

Many firms were able to keep going in those sad years and again many good ideas never saw the light of day, very often for economic reasons.

Two outstanding developments of the modern tractor were achieved. However the first was in 1932 when a pneumatically tyred tractor was introduced.

This met with considerable opposition to start with, but demonstrated its advantages to such effect that within a few years it became the chief means of gaining traction on the land.

The second was the integral mounting of the implements to the rear of the tractor and controlling lift, drop and depth by hydraulic means.

The Ferguson System

Most great men, particularly it seems, engineers, started from humble origins, most were self- educated.

Newcomen was a Blacksmith – James Watt – Karl Benz – Gotthiel Daimler and others.

The man who invented the Ferguson System – was Harry Ferguson, inventor of the Ferguson Tractor, the Ferguson farming implements and pioneer of the Ferguson System, was born on October 4th 1884 on a County Down farm in Northern Ireland.

The man who invented the Ferguson System – was Harry Ferguson, inventor of the Ferguson Tractor, the Ferguson farming implements and pioneer of the Ferguson System, was born on October 4th 1884 on a County Down farm in Northern Ireland.

As a boy his main interest was machinery and at the early age of sixteen he made his first venture into the field of practical mechanics. In 1900 he set up a small works in Belfast for the sale and servicing of the then novel motor cars and motor cycles. He soon began to race his own motor cycles and later motor cars, winning several hill climbs and similar sporting competitions.

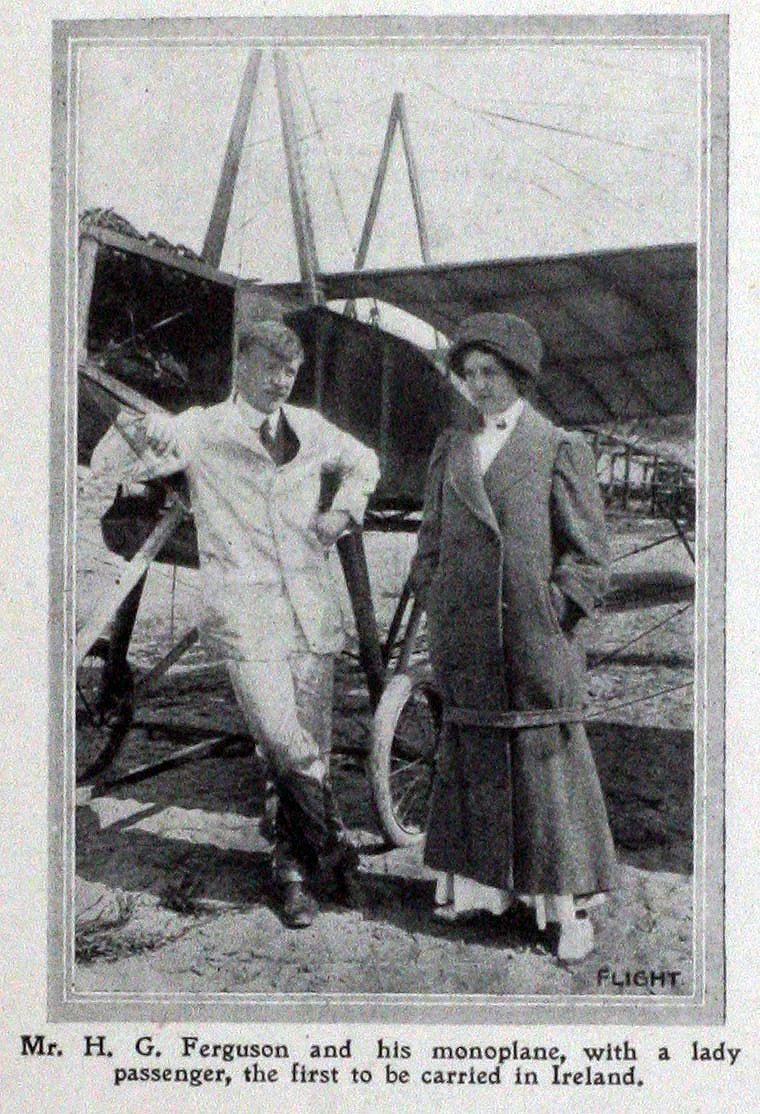

It was inevitable at that time for Mr Ferguson to turn from automobiles to aeroplanes. He designed and built a small monoplane and flew it for the first time on December 31st 1909. This was the first heavier-than-air machine to be flown in Ireland and Mr Ferguson became the first Briton to build and fly his own machine. In 1911,

Mr Ferguson returned to the automobile industry and organised a distributing agency in Belfast.

On the outbreak of war in 1914, Harry Ferguson was asked by Ireland’s Department of Agriculture to supervise the operation and maintenance of all tractors and implements throughout the country to ensure their maximum efficiency in the difficult days that lay ahead. This was the turning point in his life.

He could see that the existing models of farm production throughout Ireland, and indeed the whole world depended chiefly on animal power, requiring the use of large acreage’s simply to feed the draught animals. He could see that the animal was a definite impediment on the road of human progress.

He realised very soon that the efficient production of food is the foundation of a strong and secure nation and that a prosperous agriculture is the basic ingredient of a sound national economy. With the opinion firmly established in his mind, he reached the conclusion that only efficient mechanisation could place the agriculture of the world on the level it must reach if hunger – and the misery it breeds- were to be abolished. (Note: At that time the world population was increasing at 20 million a year, now 1979 at 70 million a year, 2 people every time your heart beats).

Having reached this conclusion, Harry Ferguson set about designing and developing a new and revolutionary type of farming equipment. The result was that in 1935, after endless experiments and concentrated engineering developments, he perfected what is now known as the Ferguson System, not only unique in itself but outstanding in that it achieved huge commercial success under the personal direction of its inventor.

It gave a new ease of implement operation, automatic depth regulation of soil engaging implements and automatic protection of implements against breakages by hidden obstructions. A new trend in the design of farm tractors and implements had begun. One by one almost all other tractor manufacturers have adopted the hydraulic lift and the mounted implement principle, though Ferguson System in some of its aspects still remains unique.

Harry Ferguson defined his plan in Detroit, Michigan on December 1st 1947 as follows:-

“My whole economic philosophy and all my efforts are guided by the knowledge that the best way to improve the total economy will be through cutting the cost of production of agricultural products, which control the cost of living”.

There must be implements of an altogether new type which will produce for the first time in history, enough food to feed all the people of the world, and also produce from the land, the source from which all wealth comes – a new wealth to enrich the world”. Everything we eat comes from the soil, except the fish and salt.

Our plant for prosperity, security and peace can be stated in two simple propositions.

- Make the good earth produce more than enough to keep its whole population in comfort and contentment.

- And, what is equally vital, produce that “more than enough” at prices which the people of the world can afford to pay.

In October 1949 – when Britain has just devalued the £ sterling in relation to the Dollar, Harry Ferguson conducted a personal campaign in the press and drew the attention of Members of Parliament to the basic fact that modernised agricultural production methods could achieve a cut of 20 per cent in the cost of living resulting in a decreasing spiral of food and all other prices, thus substituting a Price Reducing System for the curse of the age and Price Increasing System.

Echoing words used in an early definition of his plan he added: “The only obstacle for growing all the food that we need in this country (Britain), is our failure to use millions of acres capable of efficient production, and the continued use of antiquated methods of hand labour and animal power on our farms….”

The actual manufacture of farm machinery is only half the reputable manufacturers battle. Harry Ferguson pioneered service “on the farm” by which every machine is kept working on the farm as continuously and efficiently as possible. To this end a complete “School of Farm Mechanisation” was established, situated at Stoneleigh. It is staffed by fully qualified instructors and offers every facility for teaching the application of farm machinery. The school trains the company’s own staff and the representatives of its distributors, from all parts of the world, in all aspects of complete farm mechanisation and these persons in turn can pass on these benefits to the farmer, though some farmers and their workers do attend courses from time to time.

These instructional facilities are also available to university and college students, Young Farmer’s Clubs and similar organisations.

This instruction is carried outside too in the form of lectures, short courses, demonstrations, film shows, talks and discussions in conjunction with distributors educational establishments of many types, farmers’ discussion clubs and similar bodies in this country and abroad. This is considered to be a very important part of the function of Stoneleigh.

The status of agricultural engineering in the economic life of the nation has grown during the past forty years or so from a comparative Cinderella to that of major industry with a similar expansion taking place in many other parts of the world.

No so very long ago, certainly within living memory of many, the village blacksmith was the acknowledged agricultural engineer and his shop the birthplace of many a farm implement. The blacksmith’s products were generally of the simple kind like spike harrows and supplemented the more involved designs produced by a number of manufacturers of long standing. As such, the blacksmith’s knowledge of farm equipment was often surprisingly great.

He fell by the wayside along with so many other rural craftsmen during the farming depression. Today of course, he could never hope to compete with factory built equipment. Many with experience of blacksmith’s work in the old days are now trained mechanics and carry on a great tradition of service to the farmer.

1978 is a far cry from the days of the blacksmith. The agricultural engineering industry is as modern as any in Britain. Its factories cover millions of square feet, and up-to-date methods of mass production are essential to satisfy demand and maintain its products at economic prices. Harry Ferguson substituted brains for brawn, torque wrench and feeler gauges for hammer and chisel.

Agriculture can claim to be the country’s largest industry. There are various ways of justifying this statement – it occupies by far the largest proportion of the country’s area (at present), but then land is its principal raw material. Its output is the largest at some £4,000 million, some fifteen times the pre-ware level. How many other industries of long establishment can claim a figure such as this?

The industry however, employs comparatively few full time workers at under 200,000 about 2 per cent of the population and this figure is expected to fall still further. This dwindling labour force is said by some to be a drift from the land in search of more remunerative employment and by others to be a push from the land caused by increasing mechanisation. Whichever it is, and it is probably a mixture of both, it is inescapable and gives some reliable pointers to future trends in the industry.

Farmers, both large and small must plan and re-organise their activities to maintain or increase their productivity in the face of a diminishing labour force. This can only be done by utilising wherever possible, mechanical aids designed to this end. The agricultural machinery manufacturer must therefore be abreast of latest trends and must make full use of the research and design facilities available to him to produce the modern agricultural equipment capable of working under the exacting conditions met within farming the world over.

Power farming imposes strains on machines never encountered during the age of the horse-drawn implement, and unlike other engineering products designed for known and comparatively uniform conditions, they must work under very widely varying conditions with efficiency and reliability. They must perform under extremes of heat and cold, rough ground and smooth, hilly and level, in mud, in dust or water. In additional to this it must withstand the treatment meted out to it by brute force and ignorance.

Some notes on the personality and idiosyncrasies of Harry Ferguson:

Harry Ferguson was understandably the driving force and dominant personality behind the organisation which he built up. He was a man dedicated to his work and this with his characteristic determination made him a perfectionist. This determination was evident throughout his activities and particularly in designing the tractor and as a result he would never accept the apparently impossible.

He was designing his tractor and machinery for the small farmer, particularly the owner-driver, and therefore cheapness of manufacture was one of his main aims. Another one was that the driver should be able, after a day’s driving, to carry out other essential routine work on the farm without being unduly tired. He always had to be able to operate his machinery himself efficiently and it was an advantage, therefore, that physically he was not strong. This therefore, led to such refinements as an efficient self-starter, brakes, which did not require heavy foot pressure and many more. He also felt that the farmer’s job was to farm and not be a mechanic and the amount of time spent on mechanics should be a minimum. This led to many points of ease of maintenance and features such as the use of one spanner for all implement nuts and bolts and his insistence on greasing a nut before screwing it on.

He had idiosyncrasies largely deriving from his fanatical insistence on tidiness.

This tidiness extended beyond himself and his location to those who were with him and he even required his employees to wear single-breasted suits. The same applied to demonstrations of his machinery and these always had to be rehearsed to such an extent to ensure that the actual demonstrations were assured of success. Another essential of all his personnel was to carry a notebook in the left- hand pocket and a pencil in the left hand inside pocket of the jacket. Notes were to occupy no more than one page per day. This may give you some indication of the personality of Harry Ferguson and the determination, which led to the perfection and success of his system.

L0905 First Published 1979 © /Mike Thorne/KM

Harry Ferguson

– First flight in Ireland

THE FLYING ACTIVITIES OF HARRY FERGUSON: John Moore:

Ferguson Journal, Vol.4. No.1 Spring 1990

For those who were not able to attend the 1989 ‘FERGUSON OPEN HOUSE DAY’ last December 2nd we publish below, by popular request, the text of one of the two main lectures. John Moore of the Ulster Folk and Transport Museum has had a special interest in Harry Ferguson for many years. The Ulster museum displays the Ferguson replica monoplane (with some original parts) as well as other Ferguson farm and automobile exhibits. We will publish the text of the other main lecture by Aaron Jones, Massey-Ferguson Tractor’s managing director, in a later issue

I have been asked to consider the early activities of Harry Ferguson. in the days before he turned to the tractor and plough for which he became known internationally. As you may know we in Northern Ireland are very proud of Harry Ferguson – so much so that we have recently produced a twenty pound banknote featuring both his aircraft and the Ferguson Brown Model A tractor.

When the question “Who was the first Briton to design, build and fly his own monoplane?” is asked even many experts fail to appreciate that the answer is Harry Ferguson. Born at Growell, near Hillsborough, Co Down, on 4 November 1884 he achieved the first reason for lasting fame a quarter of a century later on 31 December 1909 in the same district. He was born into an age of rapid change. It is difficult for us, in this age of rules and regulations, to appreciate the pulsating excitement and newness of all forms of transport at the turn of the century. The old rubbed shoulders with the new. The horsedrawn vehicle with all its attendant mess and labour was giving way to the noisy, smelly internal combustion engine. The restless souls of the time looked for the thrills of speed both on the land and in the air.

Like many others, while their father was still fit to manage the farm, the elder Ferguson boys left the grinding toil, which was a normal way of life for farmers in the early years of the century, to join the industrial revolution. The eldest Joe (J.B.) was apprenticed to Combe Barbour, the mill engineers,

in Belfast. The city was then known world-wide for its linen, ship-building and engineering industries.

He had been introduced to the motor car when repairing a steam car belonging to the boss. With two colleagues, Stewart Hamilton and James A. McKee, the firm of Hamilton and Ferguson was formed. They repaired cars and motor cycles and undertook general engineering work. Harry Ferguson joined this thriving business as an apprentice in 1902.

Harry Ferguson established himself as a motor-cyclist and motorist of considerable skill and local repute. He did this in the cause of business as the partnership was dissolved and the firm of J.B. Ferguson & Co was established in 1903, Through this Harry learnt the necessity and rewards of good publicity. The firm rapidly gained the reputation of being the best machine shop in all Ireland.

In December 1903 the Wright brothers first flew. Their first efforts did not receive much publicity and they experimented more or less in secret until the summer of 1908 when they came to Europe and showed how to control aircraft.

Having seen the young-men-about-town move from cycles to motor-cycles and on to cars he believed that the next stop would be towards aircraft. In this he echoed Kenneth Grahame’s ‘Wind in the Willows’ where Mr Toad progressed from enthusiastic driving in his motor car to flying an aircraft. It was Ferguson’s intention to learn about aircraft and be in a position to satisfy the demand when it came.

Although he had not seen any aircraft Ferguson started drawing up plans for his own machine. In 1909 he visited the air shows at Rhiems and Blackpool to get first hand knowledge. His method of designing his own aircraft was much the same as used by others at the time. He took some measurements from the various aircraft he liked and went home and used a bit from here and a bit from there. This meant that the aircraft as it finally appeared had Antoinette-like wings and tail section attached to Bleriot style fuselage.

The first engine was a 30 h.p. Green. When it arrived the impetuous Harry Ferguson could not wait to have it running. It required some form of flywheel and, as it would have been extremely dangerous to fit a propeller in the crowded garage, he used an old pulley bound with piano wire to strengthen it. The engine burst into life and so did the pulley. One piece was never found again. Fortunately no-one was hurt. The Green engine was soon discarded and a 35 hp V-8 air-cooled JAP substituted. With its open exhaust ports, this engine was compared to a Gatling gun.

The months of November and December 1909 were spent in final assembly and attempts to fly at Lord Downshire’s Hillsborough Park. These tests led to a number of changes in the design including simplification of the undercarriage to eliminate the suspension which appears to have consisted of motor-cycle forks pivoted and controlled by large rubber bands. The Beedle propeller was replaced by a 76 inch diameter Cochrane.

Having decided that he was going to fly in 1909 Harry Ferguson was confronted by bad weather, rain, wind and snow. On 31 December 1909 he gave up waiting and, in spite of winds of nearly 30 mph and hilly ground, undertook some short hops. Then by taking the plane to the top of a field he opened up the throttle and his helpers let go. After a very short run he got up to a speed of 30 mph and pulled the aircraft up into the air. The speed dropped but he managed to stay up and cleared a hedge at the other side of the field to achieve a flight of 130 yards. Apparently this was more nerve-wrecking for the spectators than for the pilot who had achieved his ambition more by force of personality than by anything else.

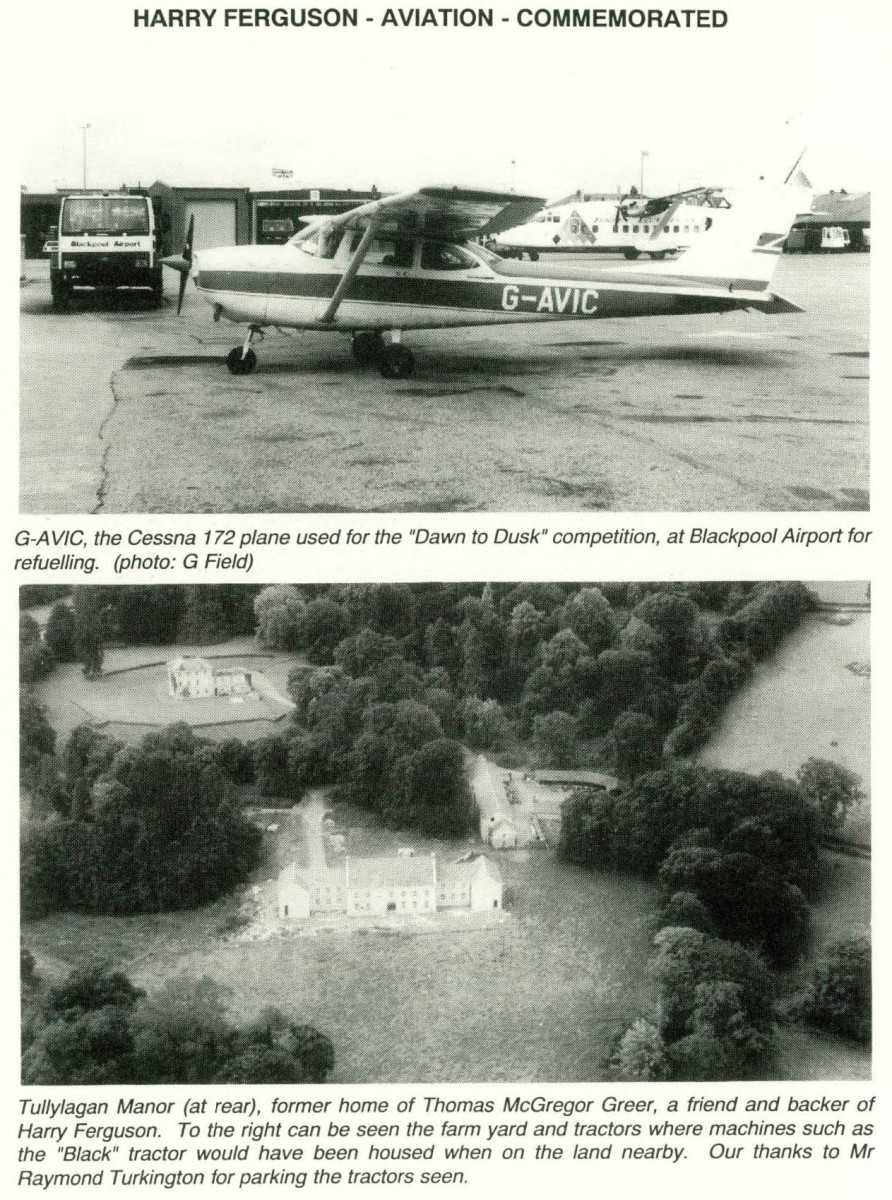

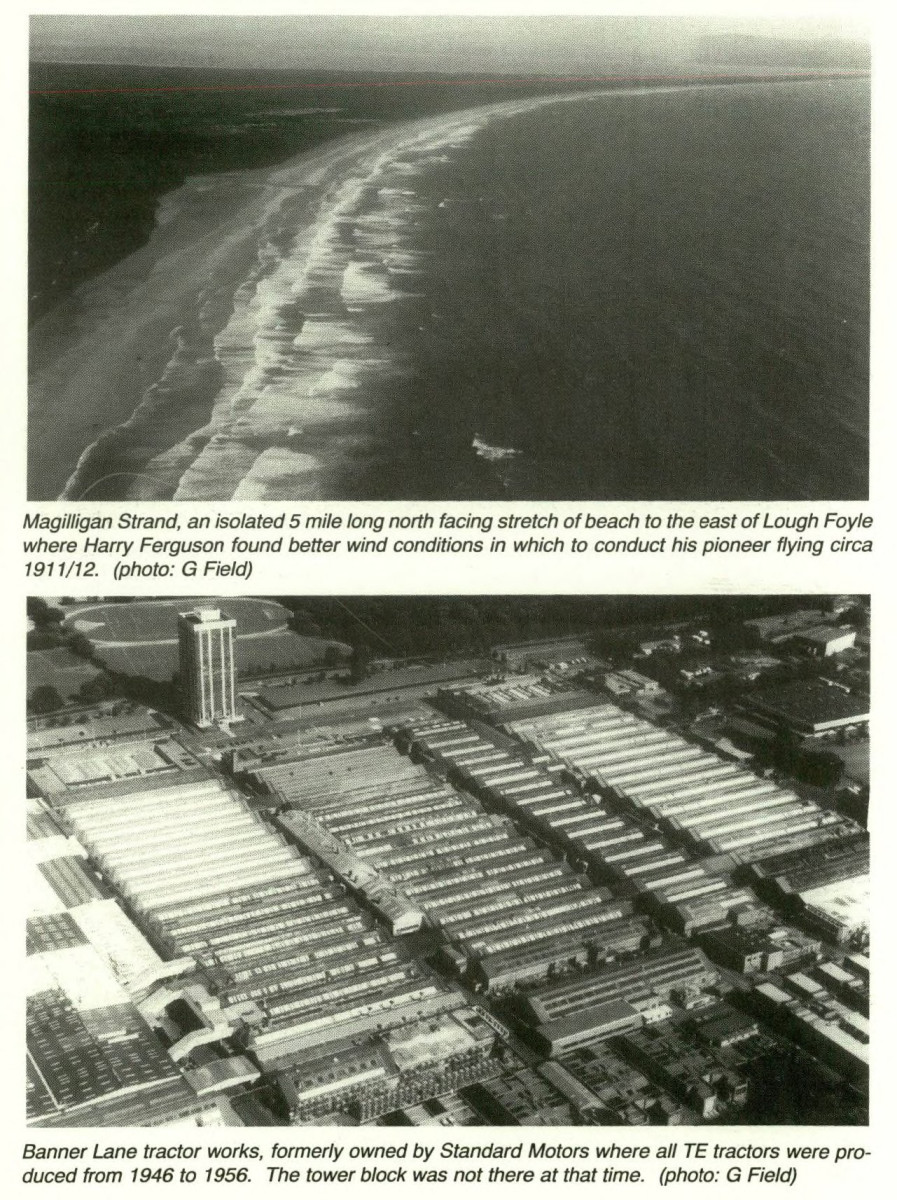

Having got into the air Harry Ferguson then met the twin problems of how to design an aircraft to fly and how to fly the product of his designs. To achieve a simultaneous solution to these two problems he had to find a better place to fly. The first place he tried was Masereene Park outside Antrim on the edge of Lough Neagh. This provided slightly better air flow conditions. He also discovered that the wide expanse of the sandbanks at Magilligan on the estuary of the River Foyle provided a very suitable site for flying.

In June 1910 the Sports Committee at Newcastle, Co Down, ‘accepted a proposal by Mr H Ferguson of Belfast to give, at a cost of £100, an aviation exhibition at the athletic meeting of 21 July. ‘ Special trains were run to this meeting. Unfortunately, Newcastle, at the point where ‘The Mountains of Mourne sweep down to the sea, ‘ suffers from considerable turbulence. It was not the best of choices for ‘the first public exhibition of Irish aeromanship ever held.’

Ferguson monoplane at Newcastle, Co. Down, © Ulster Transport Museum, Museum of Innovation, BELUM.Y16778

Crowds gathered but were disappointed. The original plan had been to give demonstrations on three consecutive days. However, the blustery and unpredictable conditions persisted and only on the evening of the third day did Ferguson even try to fly, and then it was on the beach, not in Donard Park the original planned venue.

Having assembled the aircraft and run up the engine he turned into the direction of the most frequent gusts and took off. At least he flew about 50 yards and rose 10ft. into the air. Then a wicked gust hit the aircraft and it dropped violently breaking the propeller and buckling a wheel. After replacing these items he gamely tried again but fared no better this time cracking a wing. This put further flight out of the question.

The Sports Committee realised that the problems were due to the topography and extended the time limit on their offer. After many more attempts he moved to Dundrum Bay. about three miles away and, on 8 August, took off to fly the full length of Newcastle strand and back to land at the Slieve Donard Hotel. He later described the effort, “I am sure I made at least 500 attempts to win it before actually doing so. Sometimes I would get half a mile, sometimes ~ quarter, and sometimes only a few hundred yards. Then I would get into a swirl of air, or a down-current or ‘air-pocket’ as they are called, and come crashing down. There was not a piece of the machine that at some time or other I did not break at Newcastle, and I had escapes innumerable. The aeroplane sometimes turned a complete half-somersault after landing or rather falling, and had it not been for the design of the machine, I would assuredly have been killed on many different occasions. At last, one calm day, I got up a clear hundred feet and made a three-mile flight, so winning the prize.” The £100 reward was obtained at an expenditure of considerably greater effort than several £ 1,000 prizes won by much advertised pioneers in other corners of the United Kingdom.

After this public exhibition Ferguson returned to the privacy of Magilligan where he continued to improve both his design and his flying skill. He let the people of the district see his aircraft and gave some flights. An enterprising visitor at this time was a Miss Rita Marr of Liv’erpool who travelled over to become the first woman passenger in Ireland. She had been refused trips by various English aviators of the time.

Mr T W K Clarke, the propeller manufacturer, also visited Ferguson and was taken for several flights. In October 1910, on his way back from leaving Clarke to the train at Bellarena, Ferguson was hit by a sudden squall . This upset the aircraft at a height where there was not enough room to recover thus causing a crash. Ferguson was knocked unconscious and received other bruising. The aircraft was considered a write off.

Mr T W K Clarke, the propeller manufacturer, also visited Ferguson and was taken for several flights. In October 1910, on his way back from leaving Clarke to the train at Bellarena, Ferguson was hit by a sudden squall . This upset the aircraft at a height where there was not enough room to recover thus causing a crash. Ferguson was knocked unconscious and received other bruising. The aircraft was considered a write off.

In spite of all these difficulties Harry Ferguson persevered with his intention to have an aircraft available for sale. He, therefore, took the opportunity to redesign the aircraft. The fifth variant of the Ferguson aeroplane appeared in June 1911 with a triangular fuselage and a single cabane strut formed, as before, by the extension of the undercarriage legs. The new wings were of 32 foot span, the reduction being achieved by the lighter construction of the aircraft.

He also spent the winter improving’ the tune of his 35 hp JAP engine. In converting this previously somewhat temperamental engine into a reliable, smooth, power unit he eliminated much of the trouble which had plagued him in earlier test flying. The fall-off in power which accompanied long flights could well have been a contributory factor to his October accident at Magilligan.

By June 1911 Harry Ferguson had broken away from his brother J. B. The amount of time being spent on the aircraft with such small return must have increased the friction between them. The effort involved in setting up his own garage must have slowed down the work on the aeroplane. However, to save travelling time he decided to try and fly at Newtownards only ten miles from Belfast. The new aircraft proved to be extremely easy to get airborne but ‘in trying to avoid spectators he landed heavily and broke the front skid and propeller. On the next day he had a satisfactory flight of about a mile but when taxying back the skid stuck in a mud bank and the aircraft turned over and was wrecked again.

By October 1911 Harry Ferguson had rebuilt his aircraft in yet another configuration. This time he had incorporated tricycle undercarriage to prevent a repeat of the last accident.

This aircraft was replicated by Capt. Jack Kelly-Rogers of Dublin in 1976 and is on display at the Ulster Folk and Transport Museum. Having proved that his aircraft was practical and having found that there were not enough takers ready to purchase copies Harry Ferguson turned his attention to other pursuits. He was persuaded to take up less dangerous activities such as racing for Vauxhalls. He was entered for the Dieppe Grand Prix but did not actually compete. He also built up his garage business with agencies for British and American cars, Star, Vauxhall and Maxwell. This led to an agency for the Overtime tractor which provided the opportunity to be called in as an expert by the Ministry of Munitions during World War I in their attempt to increase home food production. From this exercise he saw the necessity for a plough designed to work with a specific tractor. The depression following the Wall Street crash caused Ford to stop producing Fordson tractors leaving Ferguson with the only option of producing his own tractor and plough as the ‘Ferguson System’ with which he revolutionised farming.

This aircraft was replicated by Capt. Jack Kelly-Rogers of Dublin in 1976 and is on display at the Ulster Folk and Transport Museum. Having proved that his aircraft was practical and having found that there were not enough takers ready to purchase copies Harry Ferguson turned his attention to other pursuits. He was persuaded to take up less dangerous activities such as racing for Vauxhalls. He was entered for the Dieppe Grand Prix but did not actually compete. He also built up his garage business with agencies for British and American cars, Star, Vauxhall and Maxwell. This led to an agency for the Overtime tractor which provided the opportunity to be called in as an expert by the Ministry of Munitions during World War I in their attempt to increase home food production. From this exercise he saw the necessity for a plough designed to work with a specific tractor. The depression following the Wall Street crash caused Ford to stop producing Fordson tractors leaving Ferguson with the only option of producing his own tractor and plough as the ‘Ferguson System’ with which he revolutionised farming.

© John Moore: Ferguson Journal, V4. No.1 Spring 1990

Reprunted in Journal 56, Summer 2007.

Extract from: Graces Guide 1910: Harry Ferguson: First Flight in Ireland

“THE Emerald Isle is not by any means very far behind the times in matters of practical value, and among the several flying machines which have been built and experimented with, that of Mr. H. G. Ferguson, of Belfast, appears to give very good promise of success. So far the work of trying it has been hampered by the lack of a suitable ground, but it is hoped that this will shortly be remedied. It has been located at Lord Downshire’s park at Hillsborough, but this, having proved to be too hilly, a move has been decided upon.

During the three weeks the monoplane has been at Hillsborough, the weather has been all against practice, but on the last day of the old year Mr. Ferguson, after fitting a new Cochrane propeller, was successful in getting his machine to rise and fly for 130 yards, and this in spite of a gusty wind blowing at an average rate of 25 miles an hour. During this trial Mr. Ferguson had the machine under perfect control and landed again without difficulty. The machine is a monoplane somewhat suggestive of the Bleriot cross-Channel flyer, having a supporting surface of 192 sq. ft., the main planes being 34 ft. span. They are mounted with a dihedral angle of 4°, while the angle of incidence when flying is 7°. The length of the machine is 30 ft., and it weighs 620 lbs.

It is fitted with a 7 ft. tractor, driven at a speed of 1,200 revs, per min. by a 35-h.p. 8-cyl. air-cooled J.A.P. engine, and a speed of 32 miles has to be obtained before lifting is accomplished. The monoplane was constructed entirely in the works of Messrs. J. B. Ferguson, Ltd., of Belfast, and was designed by Mr. H. G. Ferguson after studying the various aeroplanes which took part in the Rheims and Blackpool meetings. The owner hopes to be the first to fly across the Irish Channel, and moreover to accomplish it before long.”

Harry Ferguson’s Flying Exploits